Top 8 Screed Drying Myths (And What Actually Works)

When it comes to screed drying, misinformation spreads fast on construction sites. From “just give it time” to “just open the window,” these myths can quietly cause delays, failed flooring, and costly rework.

Let’s set the record straight.

Below are the top 8 screed drying myths and what actually works if you want your project to stay on programme.

Myth 1: Screed Just Needs Time to Dry

The myth: “Leave it long enough and it’ll be fine.”

The reality: Time alone doesn’t remove moisture, conditions do. High humidity, cold temperatures, and poor airflow can stall drying indefinitely. Screed left to “dry naturally” often remains too wet beneath the surface.

What works: Controlled drying with dehumidification and monitoring.

Myth 2: Heat Dries Screed Faster

The myth: “Turn the heaters on and it’ll dry quicker.”

The reality: Heat without moisture removal can actually slow drying by increasing humidity and causing condensation. Warm, wet air has nowhere to go.

What works: Heat combined with dehumidifiers to actively remove moisture.

Myth 3: If It Looks Dry, It Is Dry

The myth: “The surface looks fine, crack on.”

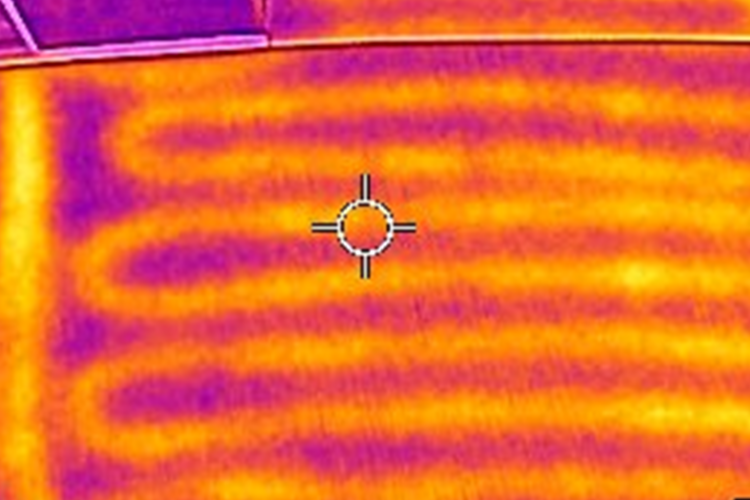

The reality: Screed often dries from the top down. It may look dry while still holding dangerous moisture levels below the surface.

What works: Proper screed moisture testing before installing floor coverings.

Myth 4: Opening Windows Speeds Up Drying

The myth: “Let some fresh air in.”

The reality: In the UK, external air is often damp, especially in winter. Opening windows can introduce more moisture and destabilise drying conditions.

What works: Sealed environments with controlled airflow and dehumidification.

Myth 5: All Screeds Dry at the Same Rate

The myth: “Drying time is always the same.”

The reality: Drying rates vary depending on screed type, thickness, site conditions, and whether underfloor heating is present.

What works: A site-specific drying strategy, not assumptions.

Myth 6: Faster Drying Always Means Poor Quality

The myth: “If it dries quickly, it must be wrong.”

The reality: Uncontrolled drying is the problem, not speed. When done professionally, accelerated drying is safe, compliant, and effective.

What works: Accelerated screed drying using controlled equipment and monitoring.

Myth 7: Moisture Testing Is Optional

The myth: “We’ve done this a hundred times, no need to test.”

The reality: Skipping testing is one of the biggest causes of flooring failure and warranty disputes.

What works: Documented testing to prove readiness.

Myth 8: Domestic Dehumidifiers Are Good Enough

The myth: “A dehumidifier is a dehumidifier.”

The reality: Domestic units lack the capacity and reliability required for construction environments and large screeded areas.

What works: Industrial-grade dehumidifiers designed for site conditions.

The difference between failed floors and successful handovers often comes down to control, monitoring, and expertise.

That’s where ForceDry comes in.

We provide:

- Accelerated screed drying solutions

- Professional dehumidification

- Moisture testing and reporting

- Support for underfloor heating systems

- Programme focused drying strategies

- No guesswork. No myths. Just results.

Don’t Let Myths Cost You Time and Money

Screed drying mistakes don’t always show up immediately, but when they do, the impact can be severe.

If your project depends on screed drying properly and on time, it pays to rely on what actually works.

Speak to ForceDry today to discuss a drying strategy that keeps your project moving and your floors protected. Call the team today on 03301 244 100 or fill in our form here.

Related Blog Posts