Traditional Drying vs Accelerated Screed Drying, What’s the Real Difference?

When it comes to floor construction, time is money. Yet screed drying is often treated as a waiting game one that can quietly derail programmes, delay floor finishes, and add unexpected costs.

So what’s the real difference between traditional screed drying and accelerated screed drying? And when does it make sense to move beyond natural drying methods?

Let’s break it down…

What Is Traditional Screed Drying?

Traditional screed drying relies on natural evaporation. After the screed is laid, moisture slowly leaves the material over time, aided only by ambient conditions such as temperature and airflow.

Typical characteristics of traditional screed drying:

- No mechanical drying equipment

- Dependent on site conditions

- Drying rates can be slow and unpredictable

- Often quoted as 1mm per day (under ideal conditions*)

In reality, ideal conditions rarely exist on UK construction sites, especially during colder months.

The Challenges of Traditional Screed Drying

While traditional screed drying may appear cost-effective initially, it can introduce significant risks:

- Cold weather delays during autumn and winter

- High humidity slowing evaporation

- Programme uncertainty

- Risk of floor failures if coverings are installed too early

For projects operating to tight deadlines, traditional drying often becomes the critical path and the biggest bottleneck.

What Is Accelerated Screed Drying?

Accelerated screed drying is a controlled process that actively removes moisture from screed using specialist equipment and techniques.

At ForceDry, accelerated drying is designed to:

- Reduce drying times dramatically

- Create consistent, controlled conditions

- Allow earlier moisture testing and floor installation

Rather than waiting weeks or even months projects can move forward with confidence.

How Accelerated Screed Drying Works

Accelerated screed drying typically involves:

- Controlled heat input

- High-capacity dehumidification

- Air movement to encourage moisture extraction

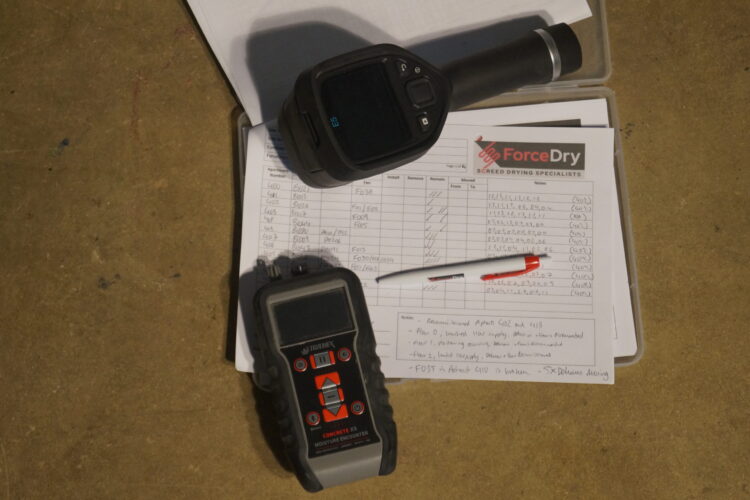

- Continuous monitoring and moisture testing

This approach ensures moisture is actively removed, not just left to evaporate naturally.

Traditional vs Accelerated Screed Drying: Key Differences

| Traditional Screed Drying | Accelerated Screed Drying |

| Passive process | Active moisture removal |

| Weather dependent | Controlled conditions |

| Slow drying times | Significantly faster |

| Higher risk of delays | Predictable programmes |

| Limited oversight | Professional monitoring |

When Is Accelerated Screed Drying the Right Choice?

Accelerated screed drying is particularly valuable when:

- Programmes are under pressure

- Winter conditions slow natural drying

- Floor finishes need installing quickly

- Delays could trigger liquidated damages

- Moisture-sensitive floor coverings are specified

For many projects, the cost of accelerated drying is far lower than the cost of delays.

Why Choose ForceDry for Accelerated Screed Drying?

At ForceDry, we specialise in professional accelerated screed drying solutions tailored to live construction sites.

Our service includes:

- Site-specific drying strategies

- Industry-approved equipment

- Moisture testing and reporting

- Compliance with British Standards

We don’t just dry screed, we help protect programmes, reduce risk, and keep projects moving.

The Real Difference Comes Down to Control

Traditional screed drying leaves your programme at the mercy of the weather.

Accelerated screed drying puts control back in your hands.

If your project demands certainty, speed, and confidence in moisture levels, accelerated drying isn’t a luxury it’s a smart commercial decision.

Speak to ForceDry

If you’re weighing up traditional screed drying vs accelerated screed drying, our team can assess your site and recommend the most effective solution.

Contact ForceDry today to find out how we can help you reduce drying times and keep your project on track.

Call us on 03301 244 100 or use our online form here.

Some of our case studies.

Related Blog Posts