What is relative humidity?

Relative humidity is expressed as a percentage and is “relative” to the amount of water vapour that the air can absorb at that temperature. When the air in your project reaches a specific capacity of water vapour, it will condense as moisture, causing the air to feel damp.

Mathematically, relative humidity is the gram-per-cubic-meter (g/m3) measure of the water vapour in the air divided by the gram-per-cubic-meter (g/m3) measure of the maximum amount of moisture the air can hold at a given temperature. The resulting number is multiplied by 100 to get a percentage. Hygrometers can help measure and calculate the current relative humidity in your project.

How does relative humidity help us?

We can use the relative humidity readings to measure how the screed is drying on a project. Most timber floor finishes require a low relative humidity to be laid in order to stop them from warping, failing and de-bonding.

With warm weather predicted in the next couple of weeks, most will assume that the relative humidity within a project will be acceptable and help to dry the screed. This, regrettably, isn’t the case. Usually, screed manufacturers state that a temperature of 20 degrees Celsius and a relative humidity of 65% or lower are needed for the screed to dry out fully across the full drying time which can be as long as 60 plus days.

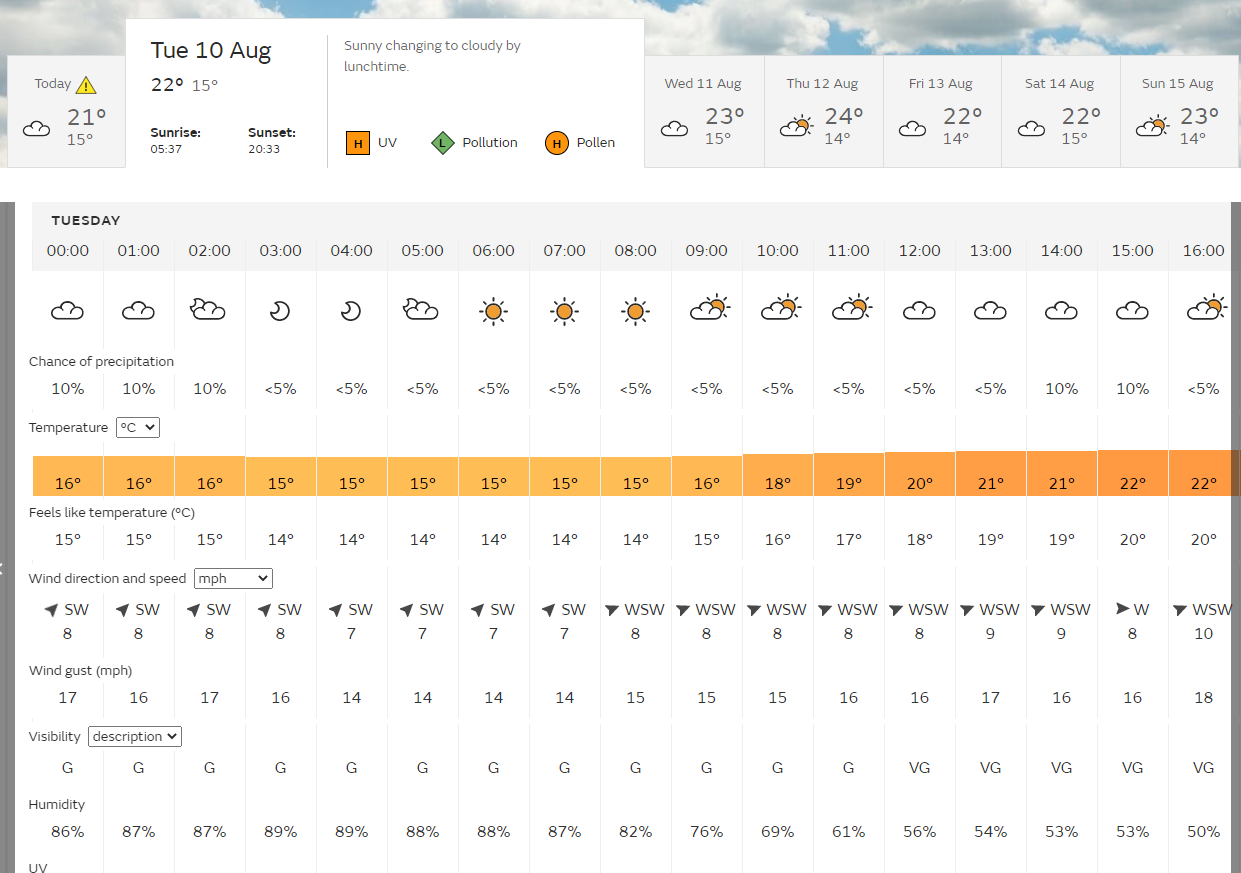

Met Office Data 2021

You can see in the above chart that in August alone, daily humidity fluctuates from 86% to 50%, these are by no means the ideal conditions for screed floors to dry. The air becomes quickly saturated and the moisture is unable to exit the screed. The UK does not experience the kind of temperature and relative humidity conditions that screed manufacturers base their drying time estimates on very often. During the hottest year on record in 2018, no consecutive 60 days delivered 20°c and 65% relative humidity so it’s not realistic to only allow for the manufacturer’s minimum drying times. During Autumn, Winter and Spring it is not realistic to expect these quoted ideal conditions at all so you should consider ways you can help create this environment and help your screed dry as quickly and safely as possible.

If you have any questions about screed drying conditions and how you can assist these, please contact us.